What are the specific applications of IGBT in new energy vehicles?

IGBT is mainly used in the three aspects of electric vehicle motor drive control system, vehicle air conditioning control system and charging pile.

01Automotive Motor Drive Control System

The main function of the motor drive system in new energy vehicles is the conversion of energy, that is, the conversion from battery direct current to motor alternating current or from motor alternating current to battery direct current. The conversion from direct current to alternating current is called inverter and the main power device used is IGBT.

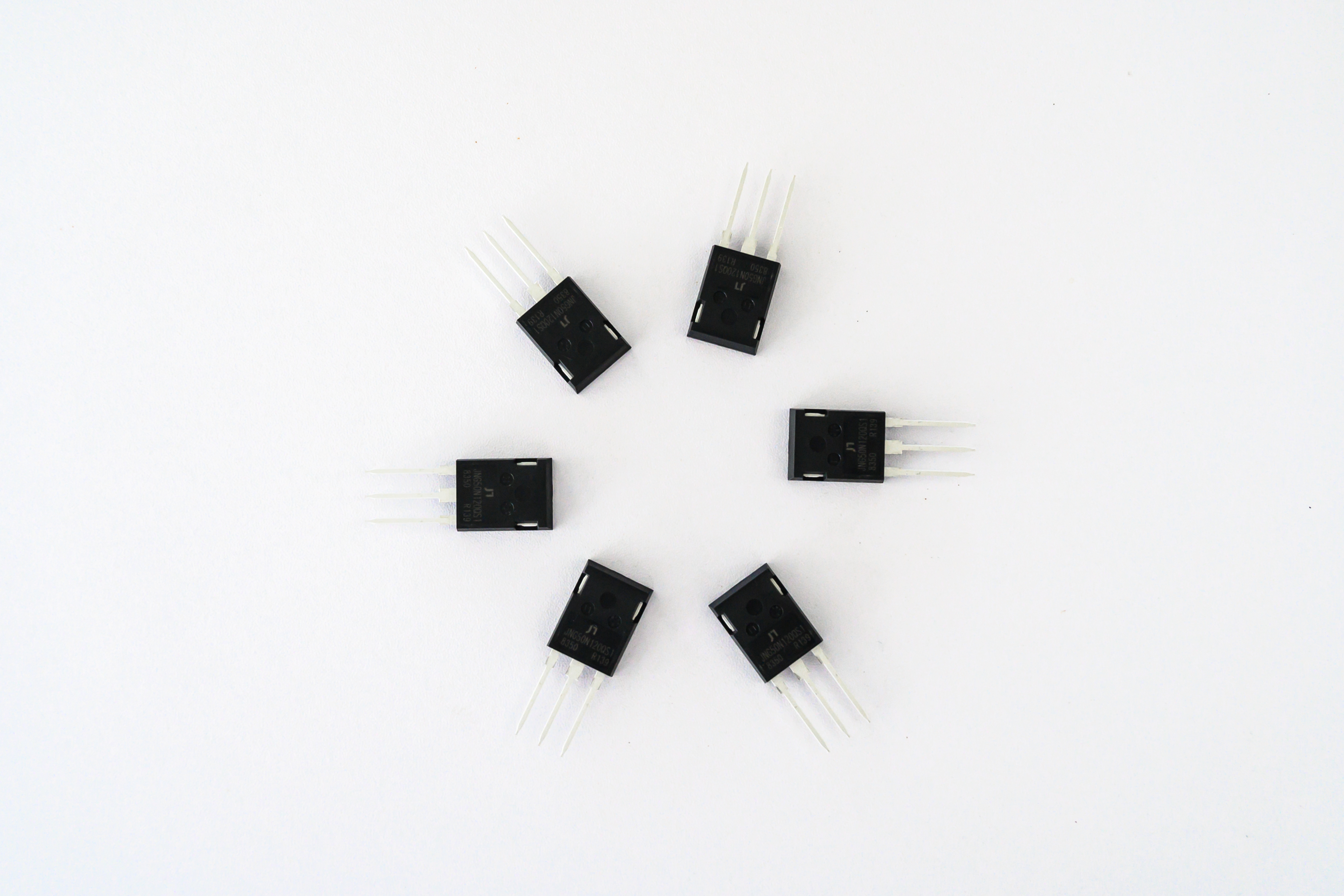

As a power conversion device, IGBT is actually more commonly used for high-voltage power conversion. During the conversion process of electric vehicles, the battery voltage is generally above 200V, the overcurrent capacity is above 300A, the breakdown voltage of power devices is about 600-1200V, and the switching frequency is within 20KHZ, so high voltage and high current can be realized through IGBT modules operation.

02 Vehicle air conditioning control system

The working principle of the electric car air conditioner is the same as that of the electric drive, that is, the inverter converts the direct current of the high-voltage battery into alternating current, and then drives the air conditioner compressor motor to work, but the power of the electric drive system is smaller than that of the electric drive system. The selection of breakdown voltage and rated current in the vehicle air conditioning control system is mainly realized by IGBT.

03 Charging pile

There are two types of charging piles, DC and AC. Taking the DC charging pile as an example, its working principle is that one end of the charging pile is connected to the AC power grid. The AC power is converted into DC power through the rectifier power module, and then passed through the capacitor voltage stabilization filter and then converted into high-frequency AC power through the IGBT power module. Finally, the transformer coupling and rectification unit convert it into different DC voltage levels to charge different electric vehicles.

In an electric vehicle, the electric drive system accounts for 15%-20% of the vehicle cost, while the IGBT module accounts for 50% of the motor drive system, which means that the IGBT accounts for 7%-10% of the vehicle cost. It is the second most expensive component besides the battery, which can be said to determine the energy efficiency of the vehicle. In addition, IGBT accounts for about 30% of the raw material cost in DC charging piles.

In a conclusion, whether in terms of function or cost, IGBT plays an increasingly important role in the field of electric vehicles.