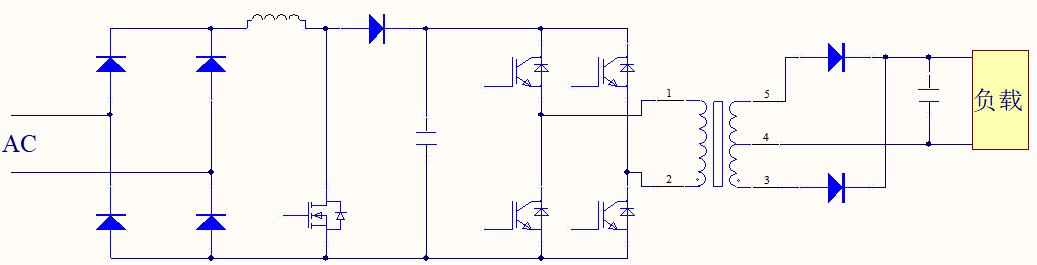

The working process of the inverter welding machine equipment is to rectify and filter the tri-phase or single-phase 50Hz power frequency alternating current to obtain a smoother direct current. After the intermediate frequency main transformer is stepped down, the alternating current is rectified and filtered again to obtain a stable DC output welding current (or the alternating current of the required frequency is output by inverter again). The control circuit of the inverter welding and cutting equipment is composed of a given circuit and a drive circuit. By processing the feedback of the voltage and current signals, the whole machine can be controlled in a cycle, and the pulse width modulation PWM is used as the core control technology, so as to obtain a fast pulse. Widely modulated constant current characteristics and excellent welding and cutting process effect.

The IGBT specially developed for the welding machine adopts Trench FSⅡ technology, which has lower turn-off loss, lower system temperature rise, stronger shock resistance and strong cost performance.