THE DIFFERENCE BETWEEN IGBT SINGLE TUBE AND IGBT MODULE

The most common form of IGBT is actually a module, not a single tube.

3 basic characteristics of modules:

·Multiple chips are assembled on a metal substrate in an insulating manner;

·Hollow plastic shell packaging, the isolation material from the air is high-voltage silicone grease or silicone grease, and other possible soft insulating materials;

·For products from the same manufacturer and the same technology series, the technical characteristics of IGBT modules are basically the same as those of IGBT single tubes with the same specifications.

The main advantages of modules are as follows.

·When multiple IGBT chips are connected in parallel, the IGBT current specification is larger.

·Multiple IGBT chips are combined according to specific circuit forms, such as half-bridge, full-bridge, etc., which can reduce the complexity of external circuit connections.

·Multiple IGBT chips are on the same metal substrate, which is equivalent to adding a vapor chamber between an independent radiator and IGBT chips, making the work more reliable.

·Multiple IGBT chips in one module have been screened by the module manufacturer, and their parameter consistency is better than that of commercially available discrete components.

·The connection between multiple IGBT chips in the module has a better circuit layout and smaller lead inductance than the external connection of multiple discrete single tubes.

·The external lead terminals of the module are more suitable for high voltage and high current connections. For the same series of products from the same manufacturer, the maximum voltage level of the module is generally 1-2 levels higher than that of the IGBT single tube. If the maximum voltage specification of the single tube product is 1700V, the module has products with 2500V, 3300V or even higher voltage specifications.

The core technology of IGBT is a single tube rather than a module. The module is actually more like a combination and assembly of an assembly and a tube core.

The differences between IGBT single tube, IGBT module and IPM module

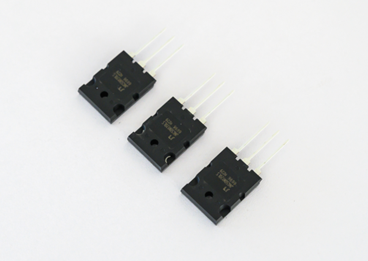

1. IGBT single tube: IGBT, the package is smaller than the module, the current is usually below 100A, and TO247 and other packages are common.

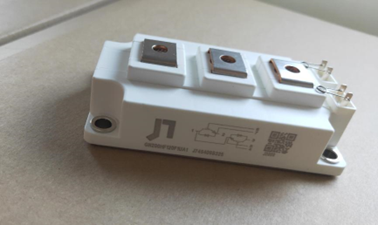

2. IGBT module: Modular packaging is to integrate multiple IGBTs into one package.

3. PIM module: integrated rectifier bridge + braking unit (PFC) + three-phase inverter (IGBT bridge)

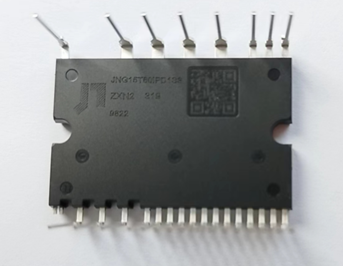

4. IPM module: an intelligent power module, an IGBT module integrating gate-level driver and numerous protection functions (overheating protection, overvoltage, overcurrent, undervoltage protection, etc.)

IGBT single tube: discrete IGBT, the package is smaller than the module, the current is usually below 50A, and TO247 TO3P and other packages are common.

IGBT module: a modularly packaged IGBT chip. Common ones include 1in1, 2in1, 6in1, etc.

PIM module: integrated rectifier bridge + braking unit + three-phase inverter

IPM module: an intelligent power module, an IGBT module that integrates gate-level drive and protection functions (thermal protection, overcurrent protection, etc.).

A smallest fully functional unit on a wafer is called a Cell or Chip cell. Generally, Chinese materials translate it as "cell", and this article is called a chip unit. Each chip unit is a complete micro-transistor, which is a micro IGBT with a P-N-P-N 4-layer structure.

The smallest unit after the wafer is divided, the chip unit that constitutes an IGBT single tube or a unit of the module is collectively called the IGBT die.

In an IGBT module, an IGBT die is called a unit of the module, also called a module unit or a die of the module. The difference between the module unit and the IGBT die is in the final product. The module unit does not have an independent package, while the die has an independent package and becomes an IGBT tube.

The control terminals of the module are not limited to the gate G, but also include electrodes that provide a reference potential for the gate drive signal, such as the secondary emitter (also called the second emitter, which is slave to the emitter E on the main terminal). The terminal electrode on the internal chip is directly led out in order to reduce the impact of large current on the gate in the main circuit). For multi-level circuit modules such as half-bridge and full-bridge, the control electrodes will also include C1E2, etc. In short, the control electrode is used in conjunction with the gate and cannot be connected to the main circuit to undertake large current transmission tasks.

For high-voltage and high-current IGBT products, some manufacturers also provide flat-panel press-fit packages, just like high-current SCR, GTO, and IGCT. Such a single-tube product has a larger power capacity than a module. Should it be called a module or a single-tube product? The industry generally still treats it as a single tube. Because the simple parallel connection of multiple chips is only a small part of the module family, it is generally called a single-tube module. Flat press-fit packaging, also known as clip-on packaging, requires a specially customized heat sink to be used with it.