Working principle and function of IGBT in medium frequency power supply

In the field of modern industrial electrical power, medium frequency power supplies are widely used, and IGBT (insulated gate bipolar transistor) plays a vital role as the core device of medium frequency power supplies. This article will deeply explore the working principle, key role, common failure modes and solutions of IGBT in medium frequency power supplies.

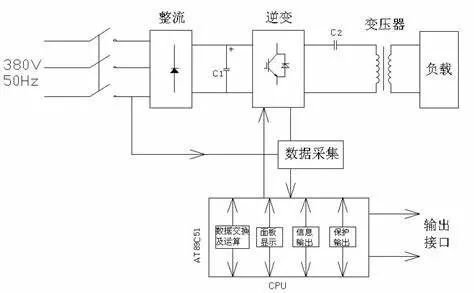

Working principle of IGBT in medium frequency power supply In medium frequency power supply, IGBT mainly works in switching state. When a forward voltage is applied to the gate of IGBT, a channel is formed inside the IGBT, and electrons can flow from the emitter to the collector. At this time, the IGBT is in the on state, and the current can pass smoothly, just like opening a smooth road, allowing large current to pass through and realize the transmission of electric energy. When the gate voltage is 0 or a reverse voltage is applied, the channel disappears, and the IGBT enters the cut-off state. The current cannot pass, just like the road is cut off, preventing the transmission of electric energy. By controlling the presence and level of the gate voltage, the conduction and cut-off of the IGBT can be accurately controlled, thereby realizing the regulation of the output current and voltage of the medium frequency power supply.

The role of IGBT in medium frequency power supply High-efficiency power conversion: IGBT can switch quickly, greatly improving the power conversion efficiency. In the medium frequency power supply, IGBT can accurately control the on and off of power, reducing the loss of energy in the conversion process, allowing the medium frequency power supply to operate at a higher efficiency and reducing production costs. Accurate frequency control: The medium frequency power supply needs to output AC power of a specific frequency. The fast switching characteristics of IGBT can accurately control the on and off time of the current, thereby achieving precise adjustment of the output frequency and meeting the needs of different industrial production for specific frequency power supplies. High voltage and high current bearing capacity: Many industrial applications need to handle high voltage and high current. IGBT can withstand high voltage and high current, ensuring that the medium frequency power supply can operate stably and reliably in complex industrial environments and provide stable power support for the normal operation of large equipment.

Common failure modes and solutions of IGBT in medium frequency power supply 1. Overcurrent failure Failure manifestation: During the operation of IGBT, the current exceeds its rated value, which may cause IGBT overheating and damage. Cause: Load short circuit, drive circuit failure, etc. may cause overcurrent. For example, if the load connected to the medium frequency power supply is short-circuited, the current will increase sharply instantly. Solution: Install a suitable overcurrent protection device, such as a fast fuse. When overcurrent is detected, the fast fuse quickly cuts off the circuit to protect the IGBT. At the same time, regularly check the load and drive circuit to ensure that they are working properly. 2. Overvoltage failure Failure manifestation: The voltage across the IGBT exceeds its withstand voltage value, which may cause the IGBT to be broken down and damaged. Cause: During the switching process, due to factors such as inductance in the circuit, voltage spikes will be generated. If the spike voltage is too high, it will cause overvoltage. In addition, abnormal power supply voltage fluctuations may also cause it. Solution: Use a buffer circuit (absorption circuit), such as an RC absorption circuit, to suppress the voltage spike. At the same time, install a voltage stabilizer to stabilize the power supply voltage and avoid abnormal voltage fluctuations. 3. Overheating fault Fault manifestation: The temperature of IGBT is too high during operation, exceeding the normal operating temperature range, affecting its performance and life, and in severe cases causing damage to the device. Cause: Poor heat dissipation is the main cause, such as improper installation of the heat sink, failure of the cooling fan, etc. In addition, long-term high-load operation will also cause IGBT to generate too much heat. Solution: Ensure that the heat sink is installed correctly and regularly clean the dust on the heat sink to ensure good heat dissipation. Check whether the cooling fan is operating normally and replace it in time if necessary. Reasonably arrange the working time and load of the medium-frequency power supply to avoid long-term high-load operation. 4. Summary As the core component of the medium-frequency power supply, IGBT has a unique working principle and powerful role, which promotes the medium-frequency power supply to play an increasingly important role in industrial production. Understanding the common failure modes and solutions of IGBT will help ensure the stable operation of the medium-frequency power supply and improve production efficiency. With the continuous advancement of technology, IGBT is also continuously upgraded, and will bring more innovation and development to the field of medium-frequency power supply in the future.